Unleashing the Power of IGBT Modules: A Comprehensive Guide

In the realm of power electronics, the Insulated-Gate Bipolar Transistor (IGBT) module emerges as a vital component, facilitating efficient control and regulation of electrical power. As technology advances, the demand for more powerful and reliable IGBT modules continues to grow across various industries, from renewable energy to industrial automation. Understanding the intricacies of IGBT modules is key to unlocking their full potential and harnessing the power they offer in enhancing performance and efficiency in diverse applications.

IGBT modules play a crucial role in modern power systems by combining the high switching speed of MOSFETs with the high voltage capability of bipolar transistors. This unique fusion allows for effective power conversion in a wide range of devices, including inverters, motor drives, and power supplies. Delving into the fundamentals of IGBT modules, including their structure, operation principles, and optimal utilization, is essential for engineers and enthusiasts looking to leverage these components for enhanced energy efficiency and performance improvements.

Understanding the Basics of IGBT Modules

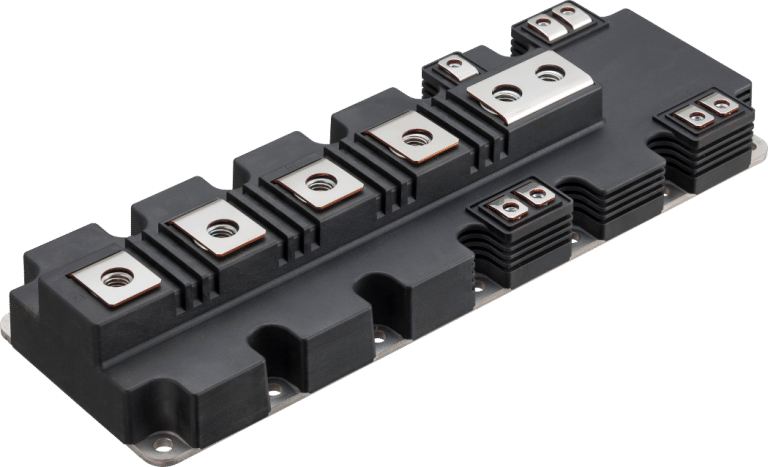

In the world of power electronics, IGBT modules are indispensable components. IGBT stands for Insulated Gate Bipolar Transistor, combining the advantages of MOSFETs and Bipolar Junction Transistors.

IGBT modules are often used in high-power applications such as motor drives, renewable energy systems, and industrial automation due to their ability to handle high voltages and currents efficiently.

The structure of an IGBT module typically consists of multiple IGBT chips connected in parallel to increase current-carrying capacity and enhance overall performance.

Applications of IGBT Modules

In the world of renewable energy, IGBT modules play a critical role in power conversion for solar inverters, wind turbines, and energy storage systems. These components enable efficient control and conversion of DC power generated by renewable sources into usable AC power for homes, businesses, and the grid.

IGBT modules are widely used in industrial motor drives to control the speed and torque of electric motors. From robotics to HVAC systems, IGBT modules provide precise and reliable motor control, resulting in energy savings, improved performance, and extended equipment lifespan.

In the automotive industry, IGBT modules are essential for electric and hybrid vehicles, powering traction inverters that control the movement of the vehicle. With increasing demand for electric transportation, IGBT modules continue to drive innovation in vehicle electrification, reducing emissions and promoting sustainable mobility.

Sign Up

Advantages and Challenges of Using IGBT Modules

One advantage of using IGBT modules is their high efficiency, which makes them ideal for applications requiring precise control over power. These modules can handle high voltage and current levels efficiently, leading to reduced energy consumption and improved overall system performance.

However, one challenge associated with IGBT modules is their sensitivity to temperature variations. Overheating can degrade the performance of these modules and even lead to failure in extreme cases. Proper thermal management is essential to ensure the reliability and longevity of IGBT modules in diverse operating conditions.

Another advantage of IGBT modules is their fast switching capabilities, which enable quick response times in applications requiring rapid switching between on and off states. This feature allows for precise control over power flow and can be advantageous in industries such as renewable energy, electric vehicles, and industrial automation.