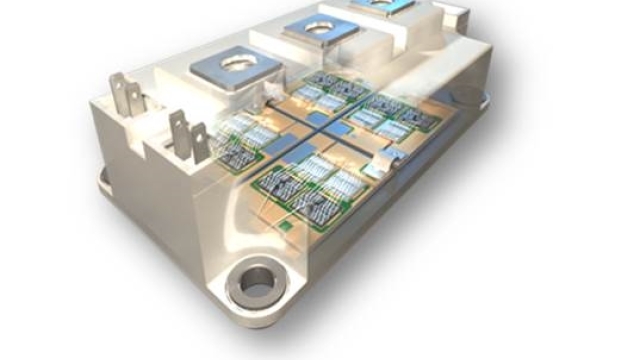

Unleashing the Power of IGBT Modules: A Comprehensive Guide

Welcome to the world of IGBT modules, where cutting-edge technology meets power efficiency. IGBT, short for Insulated Gate Bipolar Transistor, modules are at the forefront of modern power electronics, revolutionizing industries such as renewable energy, electric vehicles, and industrial automation. These modules are the powerhouse behind countless devices and systems we encounter in our daily lives, enabling efficient power conversion and control with their unique characteristics. Let’s dive into the intricacies of IGBT modules, exploring their inner workings and the myriad applications that benefit from their unparalleled performance.

Benefits of IGBT Modules

IGBT modules offer high efficiency in power conversion applications. This is advantageous as it leads to reduced energy consumption and cost savings.

Another benefit of IGBT modules is their ability to handle high power levels while maintaining minimal switching losses. This results in increased system reliability and overall performance.

Moreover, IGBT modules provide improved thermal management, ensuring optimal operating temperatures and extending the lifespan of electronic devices and systems.

Applications of IGBT Modules

IGBT modules are widely used in industrial applications such as motor drives, power supplies, and renewable energy systems. In motor drives, IGBT modules help control the speed and torque of electric motors efficiently, making them essential components in various industries.

Another key application of IGBT modules is in power supplies for energy conversion. They play a crucial role in converting and controlling high voltages and currents, ensuring stable power distribution in a wide range of devices and systems.

Furthermore, IGBT modules are increasingly being integrated into renewable energy systems such as solar inverters and wind turbines. By efficiently converting and managing power from renewable sources, IGBT modules contribute to the growth of sustainable energy solutions worldwide.

Best Practices for Using IGBT Modules

When utilizing IGBT modules, one key best practice is to carefully consider the operating conditions. It is essential to evaluate factors such as voltage, current, and temperature to ensure optimal performance and longevity of the modules. Choosing the right module based on these parameters can significantly impact the efficiency and reliability of the system.

IGBT Module

Another important practice is to adhere to proper mounting and thermal management techniques. Ensuring secure attachment of the module to a heatsink with thermal interface material can help dissipate heat effectively, preventing overheating and maximizing the module’s power handling capabilities. Proper thermal management is crucial for maintaining the module within its safe operating temperature range.

Lastly, regular maintenance and monitoring play a vital role in prolonging the lifespan of IGBT modules. Periodic inspections, including checking for any signs of wear or damage, can help identify issues early on and prevent potential failures. Additionally, monitoring parameters such as temperature and voltage during operation can provide valuable insights into the health of the modules, allowing for proactive maintenance and avoiding unexpected downtime.